Safely getting employees, clients, and customers back into buildings remains top of mind for facilities professionals of all stripes, and many are looking to technology to help with the process. UV light has tremendous potential to help mitigate airborne pathogens, but unfamiliarity with this decades-old germicide has prevented some building and facility engineers from incorporating UV-C into their multi-layered infection control protocols. Read on to get the information you need to dispel the myths and get the facts about how UV-C can help get your facility ready for life in a “post-COVID” economy.

How does UV‑C energy work?

Hundreds of scientific studies over the past century have proven the disinfectant efficacy of Ultraviolet Germicidal Irradiation (UVGI or UV‑C) energy, having first inactivated viruses and other microbes on surfaces in 1877, in water in 1910 and in air in 1935.

Through a process known as photodimerization, the UV‑C wavelength uses electromagnetic energy to destroy a microbe’s nucleic acids and disrupt its genetic building blocks. This cellular damage prevents microorganisms from infecting and reproducing.

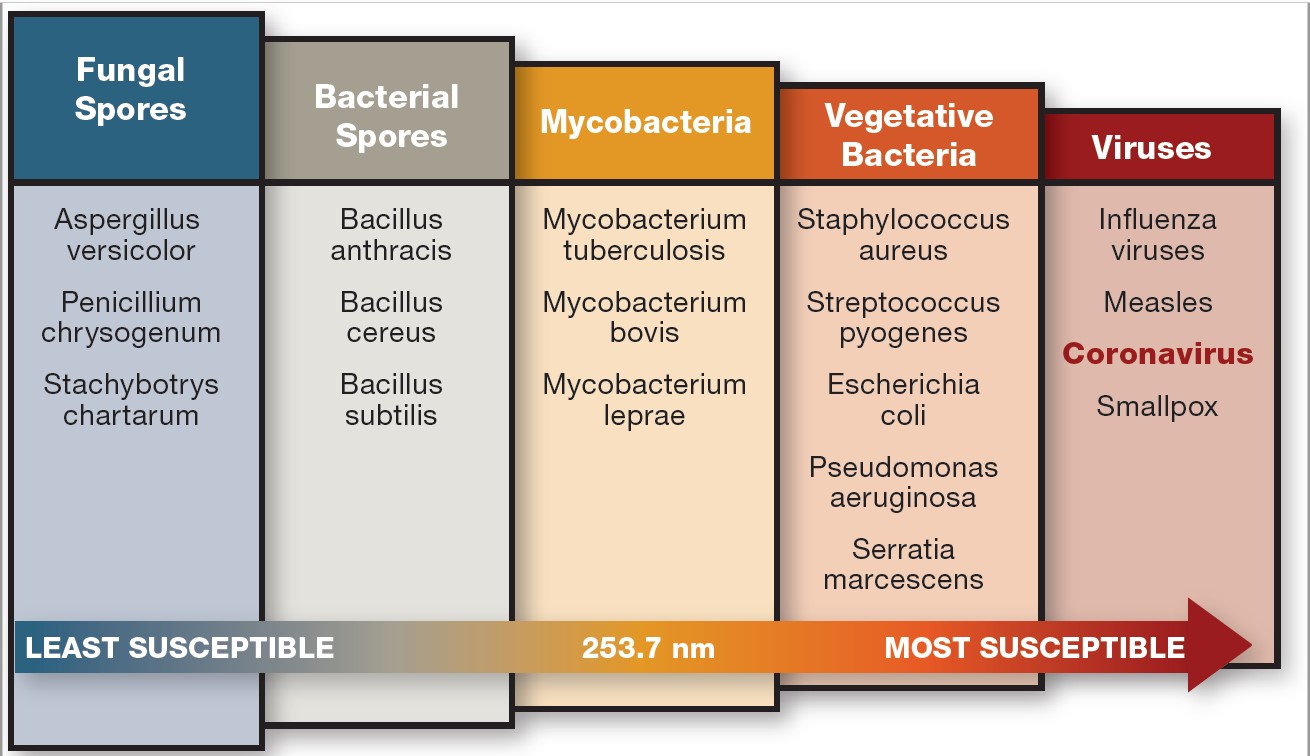

Bacteria and viruses vary in susceptibility to UV energy, with environmental organisms, fungal spores, and mycobacteria being relatively harder to kill than more rapidly replicating and non-environmental microbes and most bacteria. But even fungi are killed effectively with high-dose UV‑C. The SARS‑CoV‑2 virus, for example, is more susceptible to UV‑C inactivation than typical bacteria (see Figure 1).

Figure 1: Germicidal UV-C Inactivation of Microorganisms by Group. Data Source: ASHRAE Handbook -HVAC Applications Ch. 62. Courtesy of UV Resources.

In general, the effectiveness of UV‑C air disinfection boils down to time and intensity, (i.e., how much time/duration a pathogen is exposed to the UV‑C energy will determine how much germicidal intensity is required.)

There are operational conditions that factor into this equation including the target pathogen and its susceptibility to UV‑C; the amount of airflow (volume and velocity); the air temperature and relative humidity level; the length of exposure time (duct length); and the duct material reflectivity. Each of these variables factor into the amount of UV‑C energy necessary in any given application (installations are typically modeled to help predict individual dosage levels).

It is important to note that UV‑C operates by line-of-sight; it can only inactivate what it can see (i.e., the inside of a closed drawer cannot be disinfected unless the contents of the drawer are exposed to the UV energy).

What role can UV‑C play in safely returning-to-work?

In April 2021, the CDC acknowledged that COVID-19 is primarily communicated through airborne and not surface transmission. “Based on available epidemiological data and studies of environmental transmission factors, surface transmission is not the main route by which SARS‑CoV‑2 spreads, and the risk is considered to be low,” the CDC said.

The ASHRAE Epidemic Task Force issued concurring counsel, acknowledging the high risk of airborne transmission in its April 5, 2021 statement: “Airborne transmission of SARS‑CoV‑2 is significant and should be controlled. Changes to building operations, including the operation of heating, ventilating, and air-conditioning systems, can reduce airborne exposures.”

Moreover, because of the asymptomatic nature of this and other diseases, people can spread COVID‑19 before anyone knows they are contagious and, more importantly, before anyone can take precautions.

Therefore, it is incumbent on facility engineers and building managers to use multi-layer preventive infection-control measures, such as germicidal UV‑C, to mitigate the potential spread of airborne diseases. A multi-barrier approach helps ensure that whatever pathogen is not mitigated by one method (say filtering) is inactivated by another (UV‑C).

How can UV‑C be applied to neutralize airborne viruses?

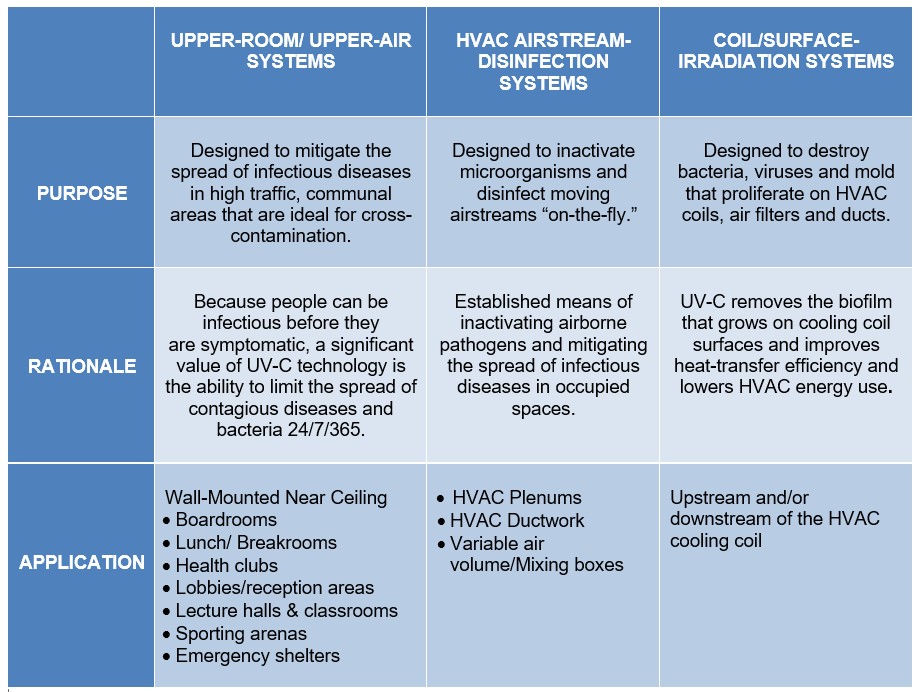

There are three primary means of applying UV‑C for air and HVAC surface protection against infectious agents: 1) Upper-Room or Upper-Air, 2) HVAC airstream disinfection, and 3) HVAC coil/surface irradiation.

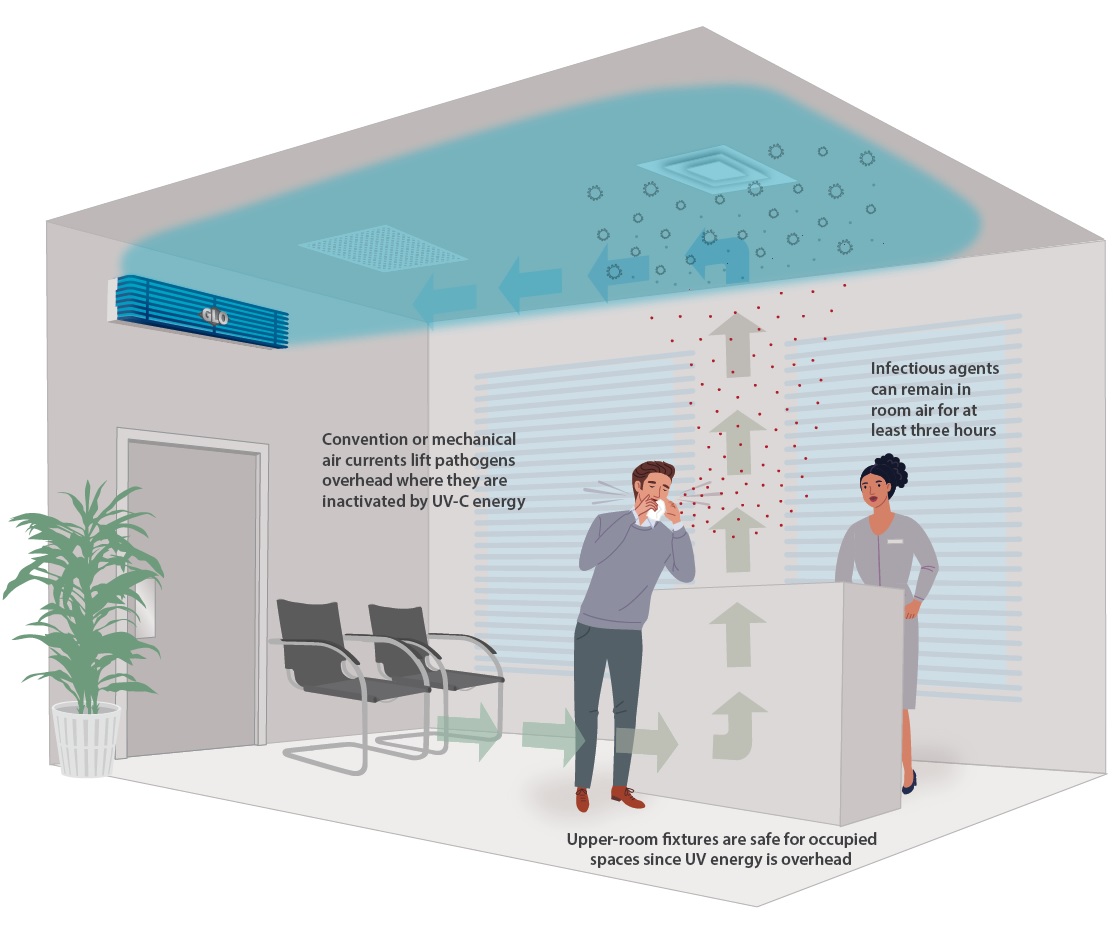

1. Upper-Room/Air systems. Wall-mounted seven-feet and higher, upper-room UV‑C fixtures generate a germicidal zone near a room’s ceiling where infectious pathogens are quickly neutralized. The natural rise-and-fall of convection or mechanical air currents lift pathogens overhead where they are inactivated in a matter of seconds (see Figure 2).

Figure 2. Upper-Room germicidal fixtures are wall-mounted seven-feet or above and use baffles to direct the UV-C energy upward and outward ensuring that no UV-C energy enters the occupied portion of the room. Courtesy of UV Resources.

Upper-room UV‑C fixtures can provide a space with the equivalent of up to 10 air changes per hour (ACH), which helps to augment other building ventilation and dilution strategies. And since UV‑C energy is overhead, upper‑room fixtures are safe for occupied spaces (see Figure 3).

Figure 3. Upper-Room UV fixtures mounted overhead near a room’s ceiling direct germicidal energy upward so that room occupants are safe to go about their normal business. Courtesy of UV Resources.

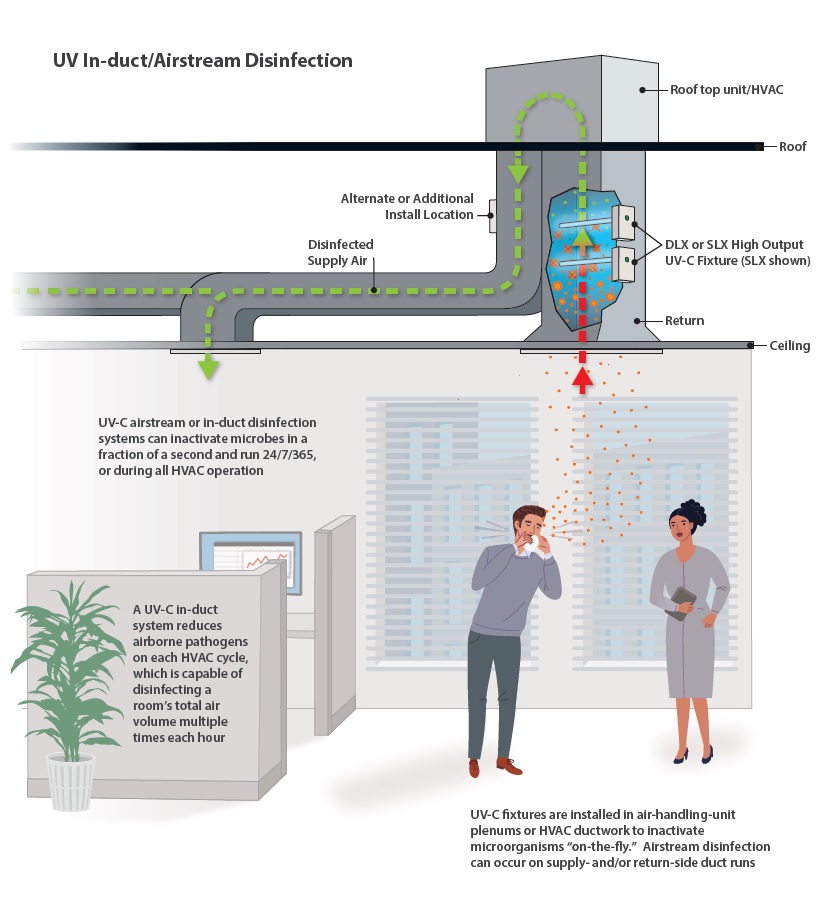

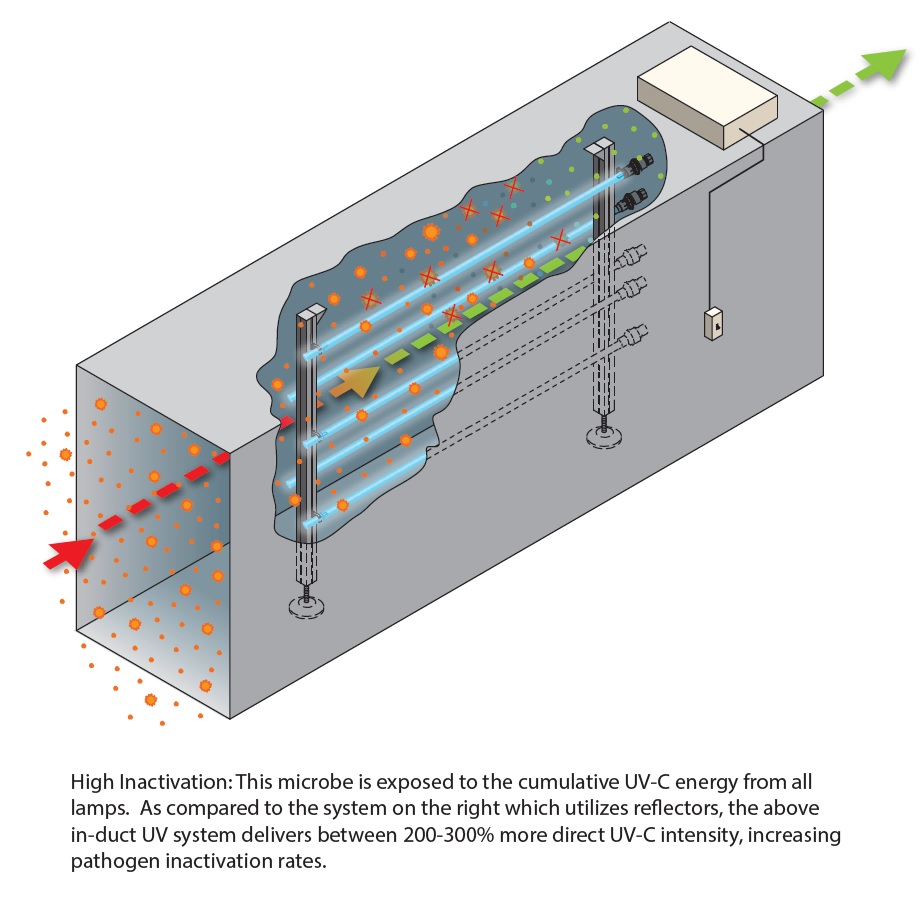

2. HVAC airstream-disinfection systems. As seen in Figures 4 and 5 below, UV‑C airstream or in-duct disinfection fixtures are installed in air handling unit plenums or HVAC ductwork to inactivate microorganisms “on-the-fly.” A UV‑C in-duct system can inactivate a microbe in a fraction of a second and can reduce pathogen concentrations on each HVAC cycle or pass. An airstream disinfection system can disinfect a room’s total air volume multiple times each hour.

HVAC UVGI systems are commonly designed for a minimum of 0.25 seconds of exposure or “residence” time for the photodimerization process to occur. The faster the air is moving (less residence time), the more UV‑C energy will be necessary to achieve the necessary dosage.

Figure 4. In-duct germicidal UV-C systems are installed in air-handling units or air distribution systems to inactivate microorganisms and disinfect moving airstreams “on-the-fly”— as well as on HVAC surfaces. Courtesy of UV Resources.

Figure 5. UV-C airstream or in-duct disinfection fixtures are installed in air handling unit plenums or HVAC ductwork (shown) to inactivate microorganisms “on-the-fly.” Microbes in this HVAC duct are exposed to the cumulative UV-C energy from all five lamps. Courtesy of UV Resources.

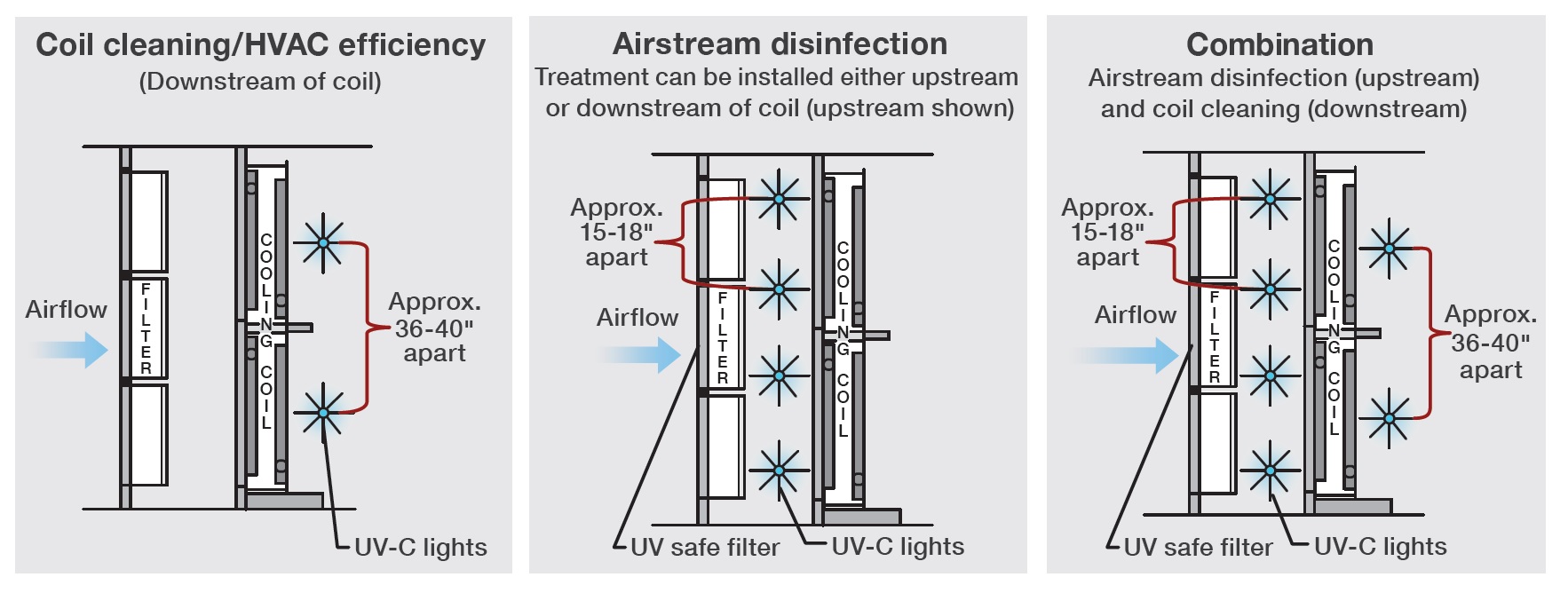

3. Coil/surface-irradiation systems are primarily installed within HVAC air-handling units to destroy biofilm, bacteria and mold that settle and proliferate on HVAC coils, air filters, ducts and drain pans (See Figure 6 below). UV‑C prevents these areas from becoming microbial reservoirs for pathogen growth that can eventually be circulated by HVAC systems. While not specifically designed for airstream disinfection, an HVAC surface irradiation system can also provide first-pass inactivation ratios of airborne pathogens of up to 30 percent, along with the primary benefits of restored cleanliness, improved heat-exchange efficiency, and lower energy use.

Figure 6: When designing a germicidal-UV disinfection system, engineers should consider the impact AHU location has on performance. Because cold air affects the output of UV-C lamps and high relative humidity affects pathogen susceptibility to UV-C, airstream disinfection can be more effective when lamps are installed upstream of a coil. In fact, moving UV-C lamps from the typical downstream temperature of 55°F to the typical upstream temperature of 70°F can increase lamp output by up to 40 percent. Courtesy of UV Resources.

How can we match a UV‑C technology to a specific application?

Selection of an air or surface disinfection system is based entirely on the application, as seen in the table below.

What is important for people to know about UV‑C in connection with COVID?

The onset of the COVID‑19 pandemic helped to highlight this germ-killing or germicidal aspect of UV‑C in both 1) HVAC in-duct, or airstream disinfection, and 2) upper‑room decontamination applications. Today, the U.S. Centers for Disease Control and Prevention (CDC) and ASHRAE include UV‑C as a recommended mitigation step to slow the spread of the SARS‑CoV‑2 virus.

The CDC’s K‑12 Schools COVID-19 Mitigation Toolkit recommends “UVGI as a supplement to kill SARS‑CoV‑2,” as part of its return to in-person-learning ventilation checklist.

Why is the UV‑C HVAC supply chain struggling to keep up with demand?

The pandemic has left no doubt that the 254 nm germicidal wavelength can inactivate the genetic material in the SARS‑CoV‑2 virus. Moreover, when aerosolized the COVID-19 causing virus is likely to be more susceptible to UV‑C damage than other coronaviruses such as SARS-CoV-1 (that led to the 2003 severe acute respiratory syndrome) or MERS-CoV (that caused the 2012 Middle East respiratory syndrome).

The CDC and ASHRAE have recommended UV‑C as one technology that can “reduce the risk of dissemination of infectious aerosols in buildings and transportation environments.”

Because of UV‑C’s historic proven effectiveness, interest in and orders for UV disinfection equipment increased exponentially during the COVID-19 pandemic. For example, last year, lighting manufacturer Signify (previously Philips Lighting), reported increasing “UV‑C light source production capacity by a factor of eight.” As a result, UV lamp manufacturers, as well as their component providers (e.g., glass suppliers), struggled to scale from what was a niche marketplace to mass production capable of meeting historic demand levels. Today, as with many other materials throughout the world, component shortages persist, however lead time for products continue to improve.

How can HVAC engineers best navigate equipment/parts supply shortages?

Facility engineers and HVAC contractors would be well advised to plan for longer lead times by placing orders as early as possible and to accept partial-order shipments. This will ensure that HVAC firms have the components/fixtures in-house (or even installed) ready to merry up to the UV‑C lamps. Specifying engineers who are unfamiliar with UV‑C and conducting their due diligence should investigate:

- Market Longevity. There are only a handful of companies that have been selling UV‑C for HVAC/R for years.

- EPA Registration. Examine a device manufacturer’s registration with the US Environmental Protection Agency (EPA) as a pesticide device-producing establishment (https://www.epa.gov/compliance/national-list-active-epa-registered-foreign-and-domestic-pesticide-andor-device-producing ).

- Industry Credentials. Make sure products meet applicable safety standards and certifications (such as UL/CUL and CSA).

- Industry Participation. Look for manufacturers that routinely author technical articles, actively serve on regulatory and standards committees, and enjoy a solid industry reputation.

Daniel Jones is co-founder and president of UV Resources, manufacturer of germicidal-UV disinfection and HVAC-efficiency solutions. The author of numerous articles on germicidal-UV airstream and surface treatment, he is a corresponding member to ASHRAE Technical Committee 2.9, Ultraviolet Air and Surface Treatment, and the standard project committee for ANSI/ASHRAE Standard 185.2. He may be contacted at daniel.jones@uvresources.com. Daniel Jones is co-founder and president of UV Resources, manufacturer of germicidal-UV disinfection and HVAC-efficiency solutions. The author of numerous articles on germicidal-UV airstream and surface treatment, he is a corresponding member to ASHRAE Technical Committee 2.9, Ultraviolet Air and Surface Treatment, and the standard project committee for ANSI/ASHRAE Standard 185.2. He may be contacted at daniel.jones@uvresources.com. |