The last thing a facility manager wants to deal with is a workplace accident or injury. Accidents in the workplace can lead to not only physical harm but also undue stress and hardship for employees, facility managers, and their employers.

To prevent accidents from happening, start with a general awareness and understanding of the safety risks in your work environment. Then, you’ll need to pair that knowledge with an action plan for accident prevention to make sure the potential risks you’ve identified do not introduce harm into your workplace.

The Impact of Workplace Accidents

Outside of bodily harm, workplace accidents present a number of challenges for business owners.

First, workplace accidents can lead to a loss of productivity. If a worker is harmed in the workplace, he or she may have to take time off of work. With the rest of the team having to pick up the slack, you’re likely to lose the productivity you would have had with a fully staffed team.

Additionally, such accidents can impact other employees and may cause them to feel unsafe in their workplace. This can translate to deflated morale and a loss of motivation, both of which can negatively impact productivity.

Moreover, a business’s negligence that results in an accident or a bodily injury can have serious financial and legal implications. Workers’ compensation claims may arise, as well as possible litigation. A single lawsuit can significantly impede business growth and can even drive a business into bankruptcy.

Preventing accidents and creating a culture of safety awareness are the best ways to ensure that the above does not happen in your place of business.

Before discussing how you can identify hazards and mitigate potential injuries in your workplace, let’s examine some recent statistics on workplace accidents.

Workplace Accident Statistics

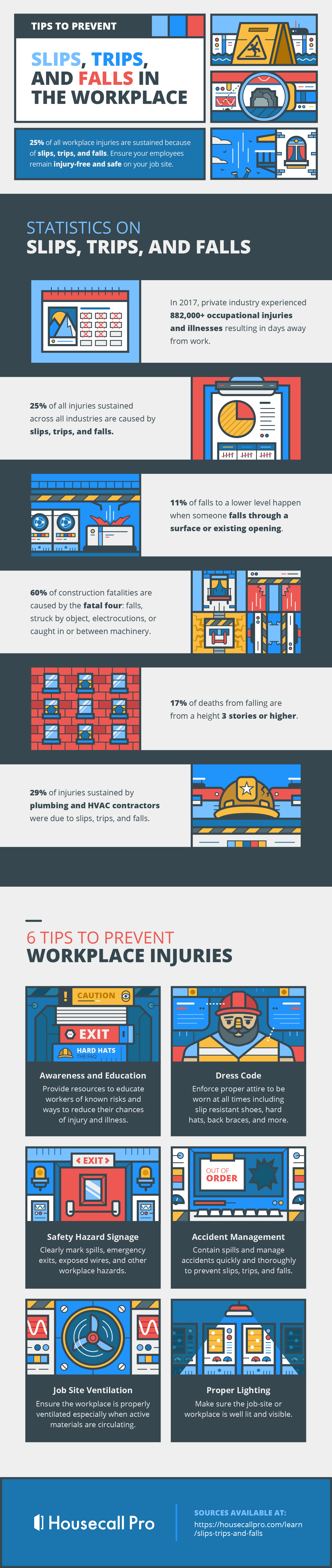

The most recent data on workplace accidents show that there were 882,730 occupational injuries and illnesses in 2017.

The Bureau of Labor Statistics (BLS) reported that of those cases:

- 11% involved overexertion in lifting or lowering.

- 64% of bone fractures were from accidents in the service industries.

- 62% of slips, trips, and falls were on the same level.

- 20% of slips, trips, and falls were from a worker falling between two or more levels.

- 15% of all nonfatal workplace injuries were from workers being struck by equipment or objects while on the job.

- 35% of cases across all industries resulted from sprains, strains, and tears.

The BLS also reported that, across all industries, more than 25% of all injuries were caused by slips, trips, and falls.

Common Causes of Workplace Accidents

One of the cornerstones of safety awareness is understanding what unique risks are associated with your work environment. With this aspect of awareness locked down, you’ll be able to craft proactive solutions for preventing these accidents.

According to the Centers for Disease Control and Prevention (CDC), slips, trips, and falls in the workplace are most likely to happen because of:

- Ladders

- Roofs

- Scaffolding

When assessing the cases reporting these accidents, the CDC found that:

- 20% of falls on the same level are from trips.

- 13% of falls on the same level are from slips.

- 11% of falls to a lower level occur when someone falls through a surface or an existing opening.

Even if your job environment does not involve workers interacting with the leading causes of slips, trips, and falls (like ladders or scaffolding), there are other areas where these accidents can occur.

When assessing your workplace, be on the lookout for areas or objects that may increase the likelihood of someone slipping, tripping, or falling. Slips, trips, and falls can also result from:

- Spills

- Slippery surfaces

- Obstructions

- Broken equipment

- Areas with a lack of safety signage

The Best Ways to Prevent Accidents at Your Facility

The best way to avoid workplace accidents is through a strategic safety plan. With proactive measures in place, you and your employees can create a culture of safety and a targeted accident prevention program.

Consider the following tips to bolster your safety efforts:

- Promote safety awareness and education with regular safety briefings and employee safety training.

- Install proper lighting to create a well-lit and visible jobsite that makes it easier for your staff to see potential risks and avoid them.

- Communicate safety hazards with adequate signage that clearly identifies hazardous areas and potential risks like obstacles, spills, toxic materials, or other hazards.

- Contain spills quickly when they happen, and remember to always have cleanup equipment readily accessible in your workplace.

- Routinely check for safety hazards, like spills or obstacles.

- Install proper ventilation to prevent toxic chemicals or other foreign particles from being inhaled by your employees.

- Enforce proper attire that’s necessary for accident prevention, like hard hats or slip-resistant shoes.

Now that you understand some of the most common causes of workplace accidents and how you can prevent them, you can enhance your own safety program. Use the tips above to draft the basis for your program and tailor the needs of accident prevention to the unique challenges in your workplace.

Emma Voss is a content marketing specialist from San Diego, where she helps create amazing content for companies like Housecall Pro. She loves learning new things, writing articles, and working on her art. When she’s not scouring the Web for the latest content marketing insights, you can find Voss hiking the San Diego hills with her French bulldog, Luna. Emma Voss is a content marketing specialist from San Diego, where she helps create amazing content for companies like Housecall Pro. She loves learning new things, writing articles, and working on her art. When she’s not scouring the Web for the latest content marketing insights, you can find Voss hiking the San Diego hills with her French bulldog, Luna. |